The Background

In banknote production—specifically watermark creation—a critical component is a multi-layer, large-area copper screen mounted on a water-permeable cylinder. This screen serves as the counterpart to a roller in the paper machine. Attached to the screen are raised structures called e-types, along with embossed impressions. As moist paper passes between the cylinder and roller, these elements apply localized pressure, forming the watermark during the subsequent drying phase.

The Challenge

Manufacturing the copper screen involves several complex processes. Initially produced in flat form, the screen must be cylindrically formed after e-types and embossed structures are welded in place. It must then be spot-welded with additional layers and finally joined along the longitudinal edges with a precision seam weld. This intricate process demanded a custom machine solution capable of delivering high accuracy, repeatability, and operational efficiency.

The Solution

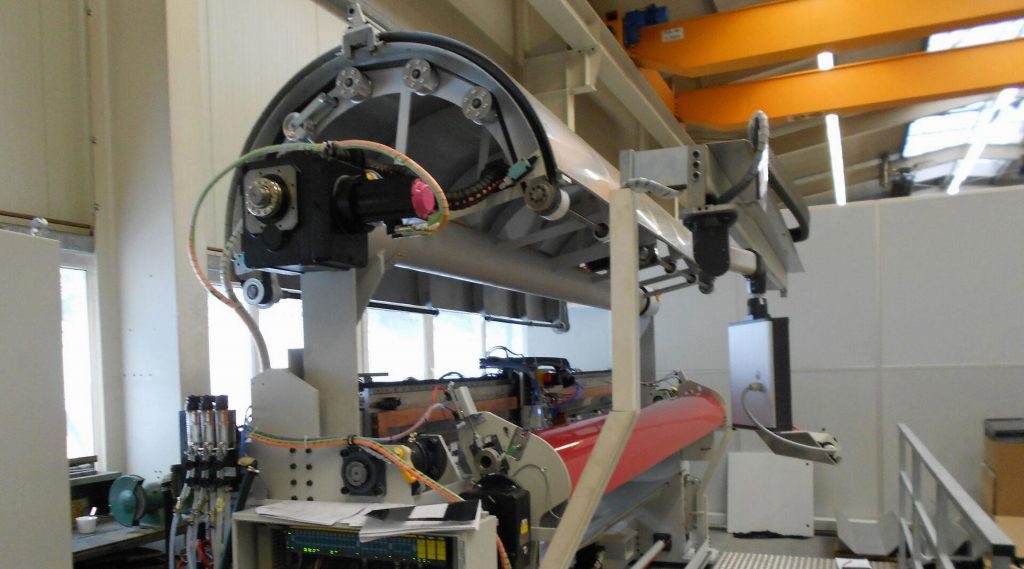

tech-solute developed a fully customized manufacturing system tailored to the specific requirements of watermark screen production. The machine automates the forming, alignment, spot welding, and seam welding processes with exceptional precision.

Beyond mechanical design and engineering, tech-solute delivered comprehensive technical documentation to support seamless integration, operation, and maintenance within the client’s production environment.

Key Technical Features

The custom manufacturing system includes:

- Integrated Quality Control – real-time monitoring ensures specification compliance throughout the process

- Precision Cylindrical Forming – transforms flat copper screens into exact cylindrical geometry

- Automated Multi-Layer Assembly – positions and spot-welds additional screen layers with micron-level accuracy

- High-Precision Seam Welding – creates consistent, high-quality longitudinal seam welds

Key Technical Features

The solution enabled the client to:

- Achieve consistent watermark quality across production runs

- Significantly reduce manual handling and associated errors

- Improve production throughput while maintaining precision standards

- Establish a reliable, repeatable manufacturing process for security printing applications

This specialized machine represents tech-solute’s capability to engineer custom automation solutions for highly demanding, precision-critical manufacturing processes in security and specialized industries.