The Background

Traditionally, steel beam machining has relied on multiple sequential processing systems. While effective, these conventional setups are space-intensive and time-consuming, often creating production bottlenecks and driving up operational costs.

The Challenge

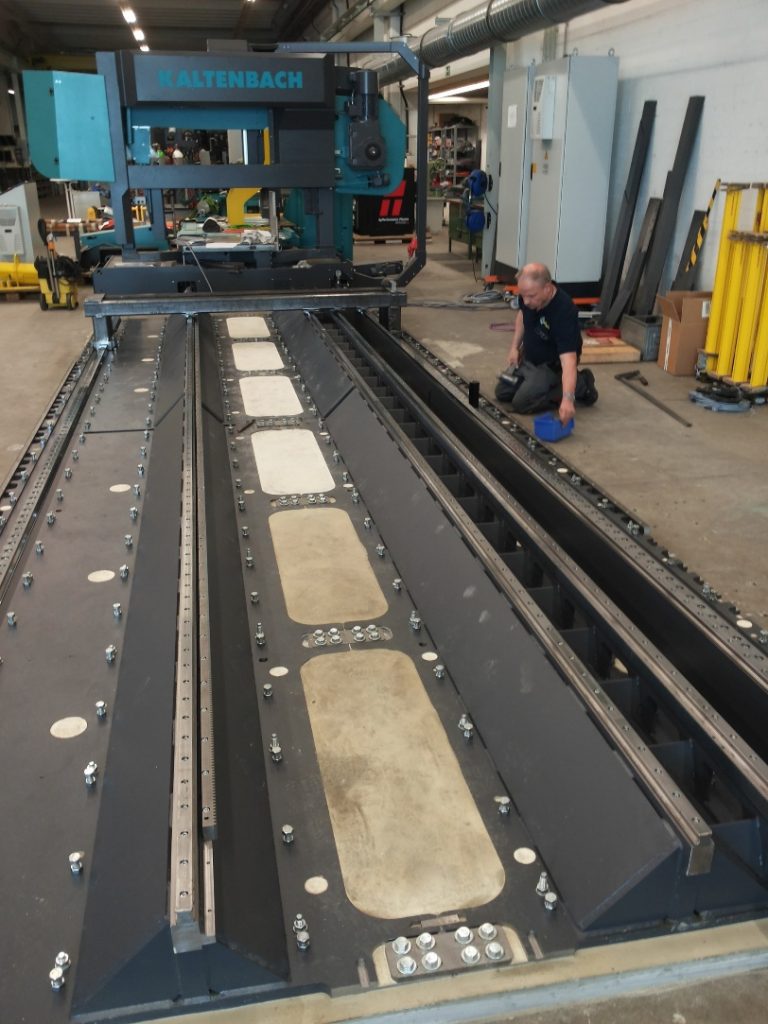

The customer sought to significantly improve steel beam processing efficiency by developing a compact, high-performance machining center capable of handling multiple operations within a single, flexible system. The objective was to increase productivity while minimizing the factory floor footprint.

The Solution

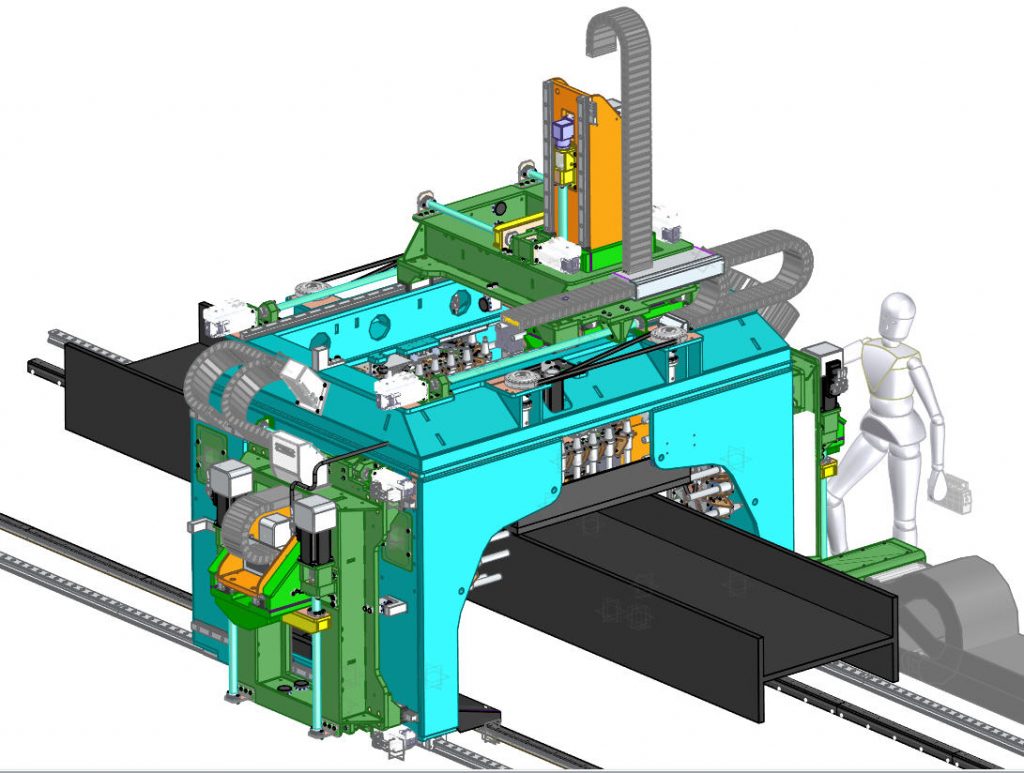

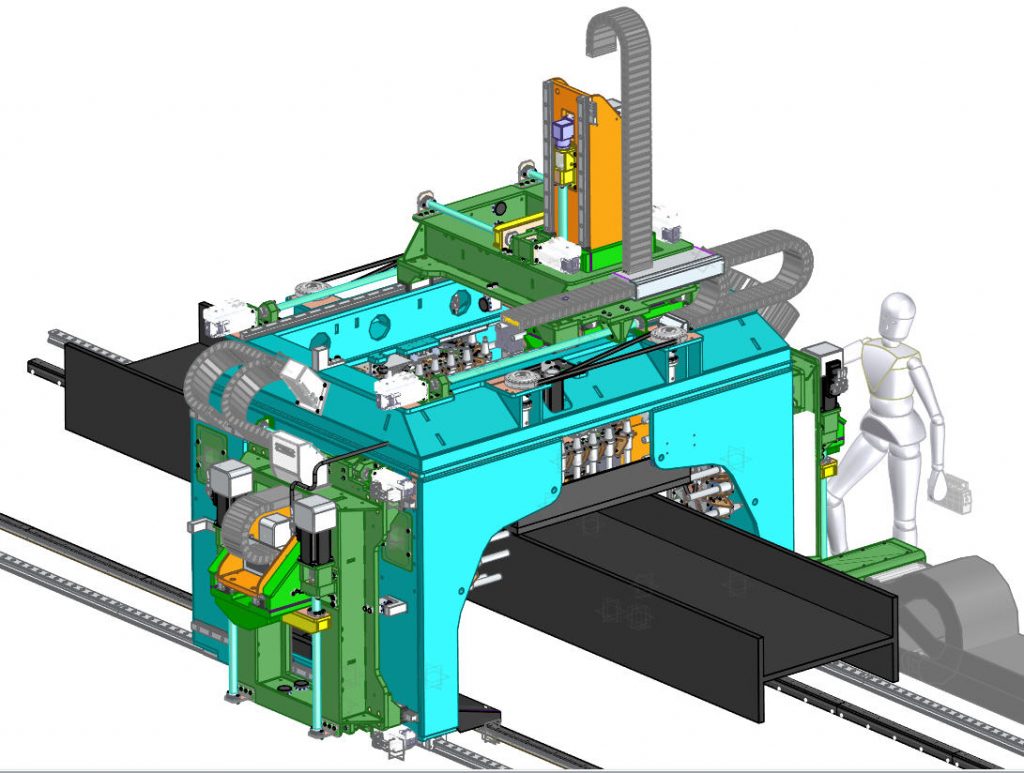

tech-solute played a pivotal role in developing HERKULES, an innovative machining system that delivers up to 80% higher productivity compared to traditional solutions—while occupying only a fraction of the floor space.

From the initial concept phase, tech-solute helped shape the vision for a fully integrated, flexible machining center. Our scope of work included:

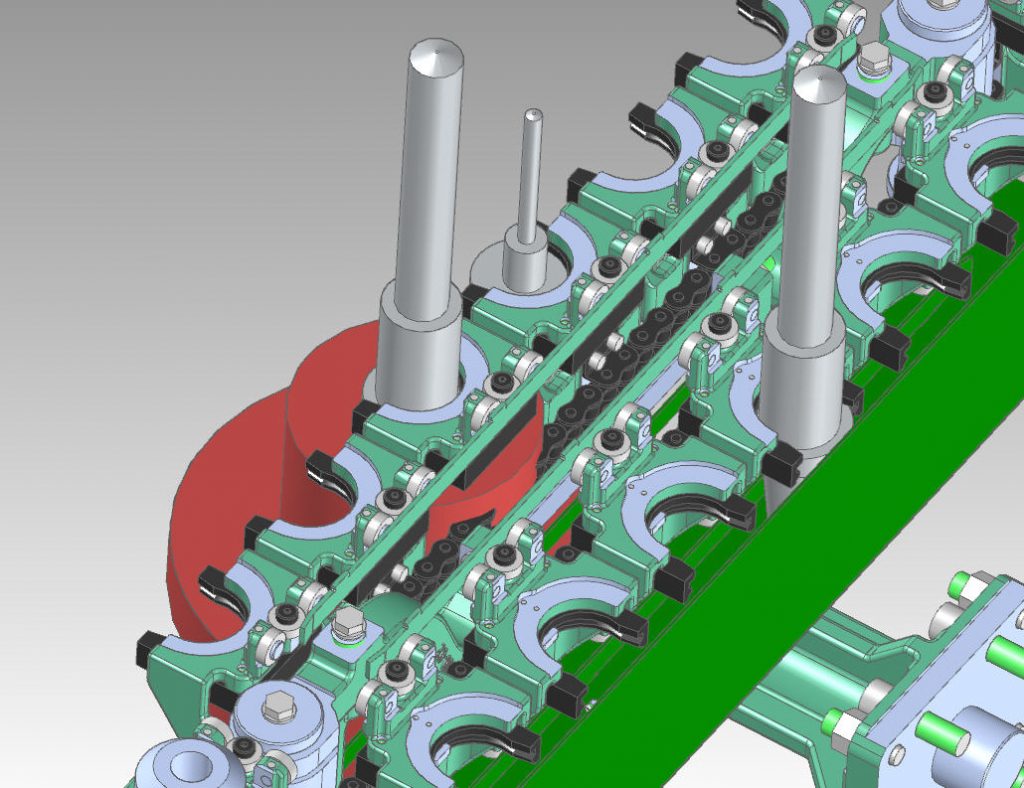

- Generating and evaluating design concepts for mechanical flexibility and modularity

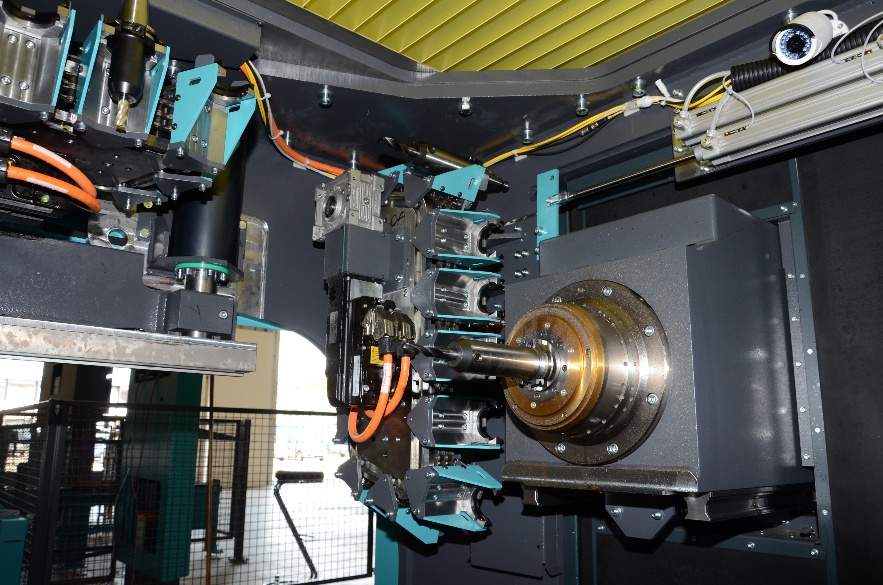

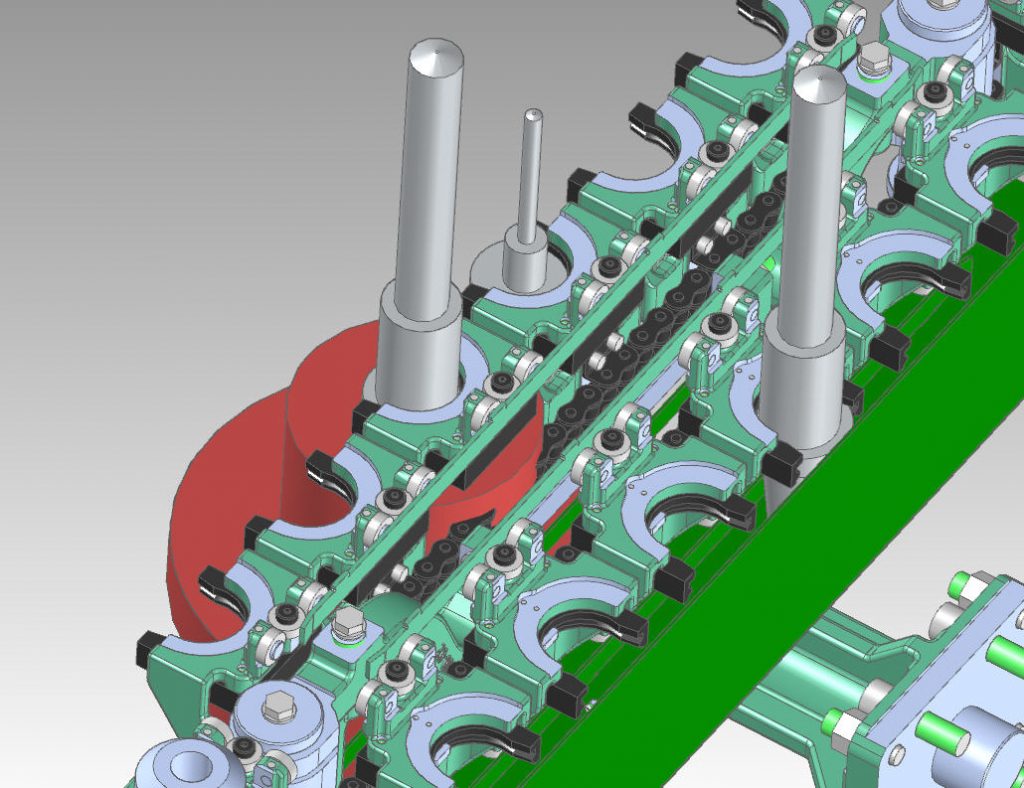

- Engineering numerous mechanical subsystems tailored to high-precision operations

- Integrating mechanical design with automation and control technologies

- Actively participating in assembly and on-site commissioning of the complete system

Through this collaborative development, HERKULES established a new standard in steel beam machining—delivering not only greater efficiency, but also enhanced adaptability for evolving manufacturing needs.