The Background

Many households today are equipped with high-performance power tools, including heavy-duty drills and cordless screwdrivers. The CoPoT project focused on ensuring these tools remain safe and intuitive for non-professional users.

Project researchers developed a smart cordless screwdriver designed to make DIY tasks faster and safer by automatically preventing improper use. The overarching goal of this collaborative research initiative was to transform conventional power tools into intelligent digital assistants.

The Challenge

How can powerful professional-grade tools be made accessible and safe for everyday users while preventing common errors and accidents?

The Solution

The CoPoT concept integrates power tools into a digital ecosystem that actively supports users and prevents misuse. Users receive virtual guidance throughout tasks, with real-time assistance and best-practice instructions delivered through a connected system. A central cloud platform provides recommended settings and task-specific guidance, while the power tool autonomously adjusts its operating parameters.

A smart toolbox serves as the central computing unit, functioning as both the user interface and coordination hub. Measurement data—collected anonymously during tool operation—is transmitted to the cloud and processed using machine learning algorithms to continuously refine operating parameters and instructional content.

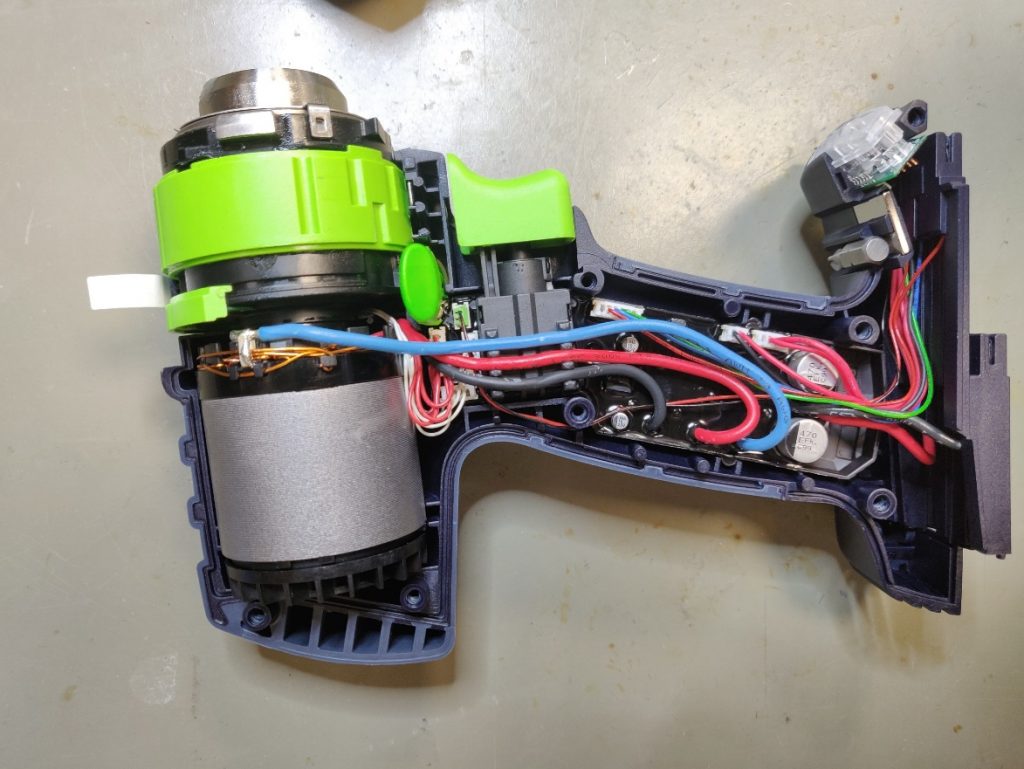

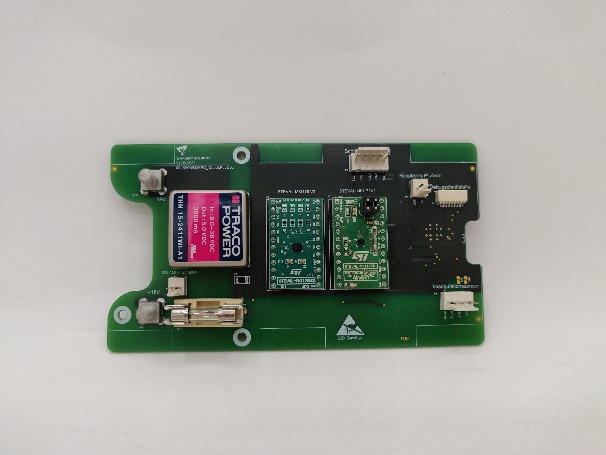

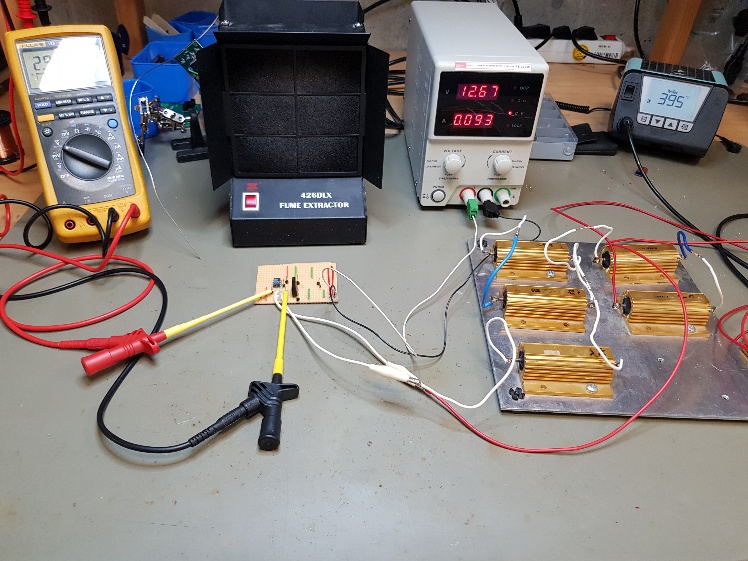

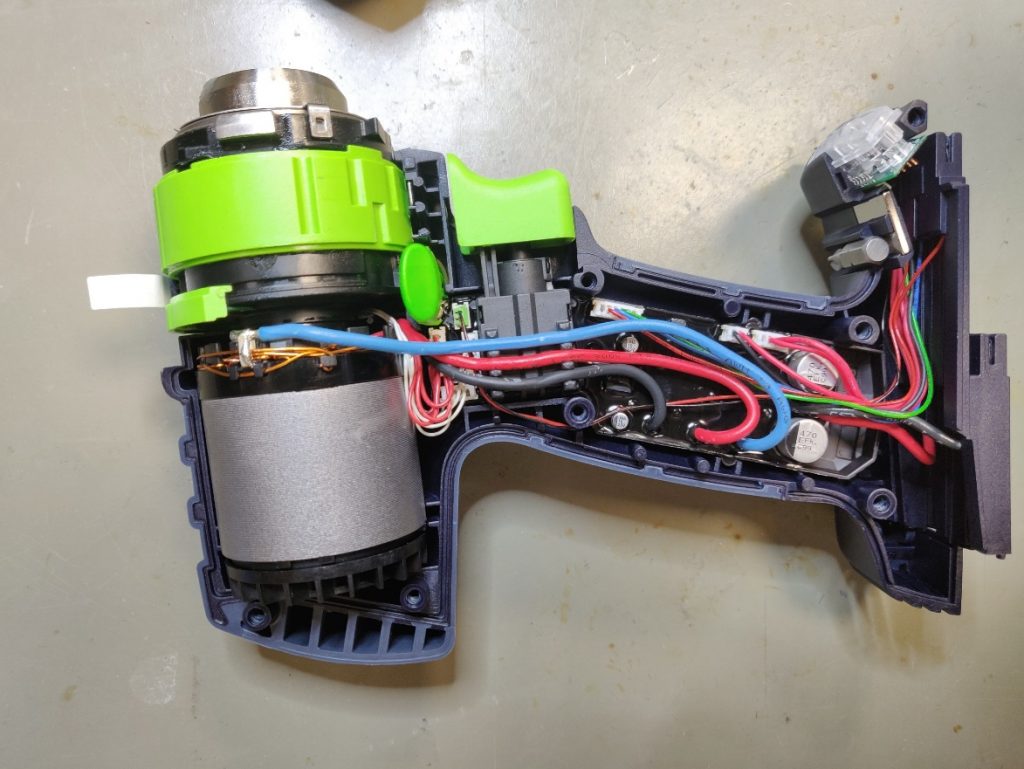

tech-solute successfully developed a prototype intermediate adapter for the Festool QUADRIVE DRC 18/4 professional cordless drill/driver, delivered in two iterations: a functional prototype and a working demonstrator. This adapter enables two intelligent operating modes:

- Drilling to Target Depth – Automatically stops at the precise depth

- Flush-Mounted Screwing – Ensures screws are driven perfectly flush with the surface

Additionally, tech-solute led the microcontroller programming within the drill driver, enabling smart features and adaptive control capabilities.

Technical Innovation

The CoPoT project demonstrates how an IoT-based digital assistant system can effectively “tame” the power of high-performance tools, reducing injury risk while ensuring more reliable and consistent results. The system enables faster, more accurate work by dynamically adjusting parameters such as torque and rotation direction based on the upcoming task.

The prototype system comprises:

- A smart cordless screwdriver with integrated sensors

- A toolbox functioning as the central computing unit

- A web-based application for user control and task management

Through integrated sensors, the system detects task completion (such as a screw being fully inserted flush) and automatically stops the screwdriver. It then reconfigures the tool for the next step, ensuring seamless workflow efficiency. Step-by-step instructions and task-specific guides are accessible via the web interface, with users retaining full control throughout the process.

Impact and Future Applications

Insights from CoPoT lay the foundation for further development of digitally assisted craftsmanship. While initially targeting DIY users, the system applies equally well to professional environments, including construction sites and workshops.

Furthermore, anonymous device data analysis introduces additional opportunities for machine learning, process documentation, and product development insights. This project represents a significant step toward the future of smart, connected tools that enhance safety, efficiency, and user experience across both residential and professional settings.